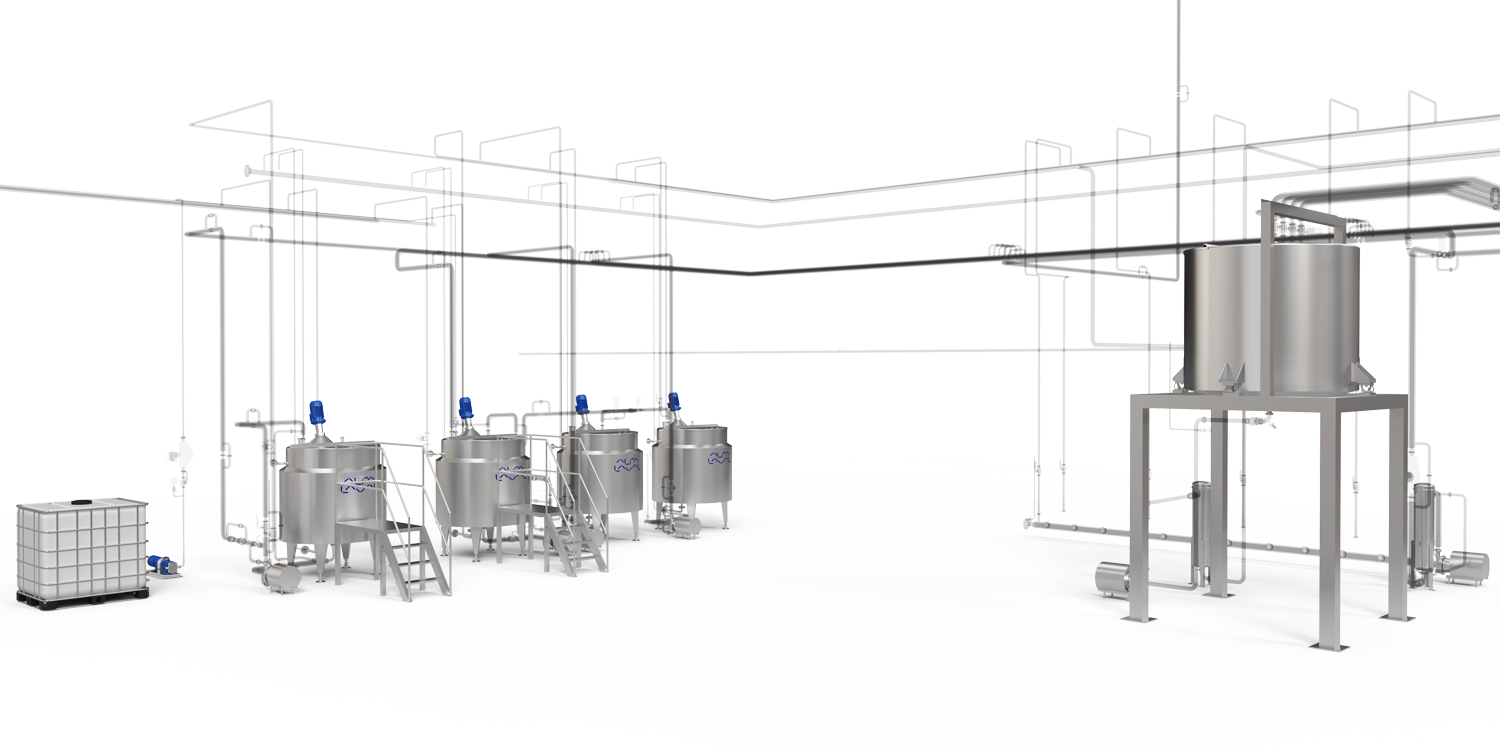

Habka wax soo saarka margarine wuxuu ka kooban yahay shan qaybood: wajiga saliidda leh diyaarinta emulsifier, wajiga biyaha, diyaarinta emulsion, pasteurization, crystallization iyo baakadaha.Wax soo saar kasta oo xad-dhaaf ah ayaa lagu soo celiyaa iyada oo loo sii marayo unug dib-u-shaqayn joogto ah oo lagu sameeyo haanta emulsion.

Wajiga saliidda iyo diyaarinta emulsifier ee wax soo saarka margarine

Bamku wuxuu ka gudbiyaa saliidda, baruurta ama saliidda la isku daray ee haamaha kaydinta iyada oo loo marayo shaandhada una gudbisa habka miisaanka.Si loo helo miisaanka saxda ah ee saliidda, taangigan ayaa lagu rakibay korka unugyada rarka.Saliidda isku-darka ah ayaa lagu qasi karaa iyadoo loo eegayo habka loo kariyo.

Diyaarinta Emulsifier waxaa lagu fuliyaa iyadoo saliid lagu qaso emulsifier-ga.Marka saliiddu gaadho heerkul ku dhow 70°C, emulsifiers sida lecithin, monoglycerides iyo diglycerides, sida caadiga ah qaab budo ah, ayaa gacanta lagu daraa haanta emulsifier.Walxaha kale ee saliidda ku milma sida midabaynta iyo dhadhanka ayaa lagu dari karaa.

Marxaladda biyaha ee wax soo saarka margarine

Taangiyo dahaaran ayaa loo keenay wax soo saarka wajiga biyaha.Mitirka socodka ayaa biyaha ku shuba haanta halkaasoo lagu kululeeyo heerkul ka sarreeya 45ºC.Walxaha qallalan sida milix, aashitada citric, hydrocolloids ama budada caanaha la dubay ayaa lagu dari karaa haanta iyadoo la isticmaalayo qalab gaar ah sida qasiyaha funnel funnel.

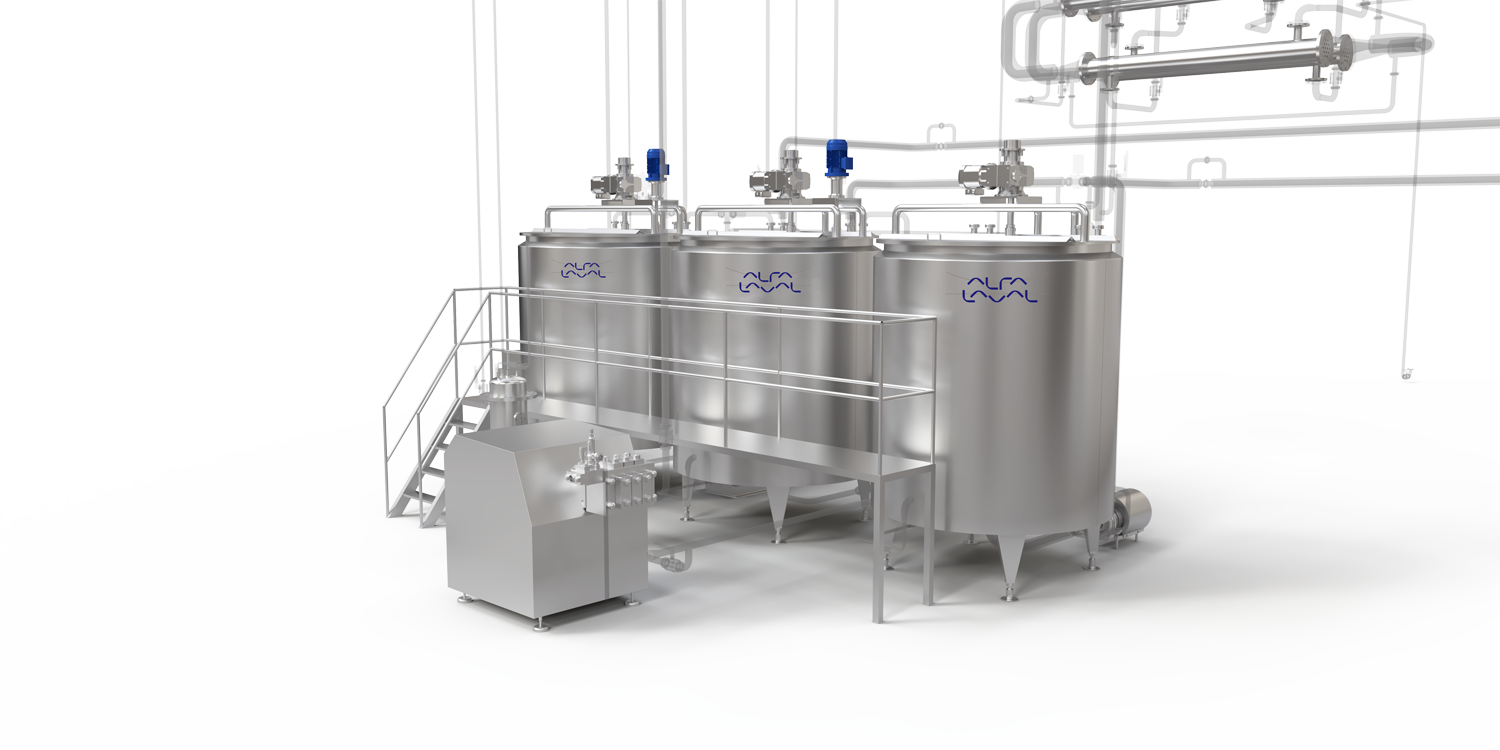

Diyaarinta Emulsion ee wax soo saarka margarine

Emulsion-ka waxaa lagu diyaariyaa qiyaasta saliidaha iyo dufanka leh emulsifier-ga isku darka ah iyo marxaladda biyaha ee sida la sheegay.Isku darka wajiga saliida iyo wajiga biyaha ayaa ka dhaca haanta emulsion-ka.Halkan, maaddooyinka kale, sida dhadhanka, udgoonka iyo midabka, ayaa laga yaabaa in lagu daro gacanta.Bamka wuxuu u gudbiyaa emulsion-ka ka dhasha haanta quudinta.

Qalab gaar ah, sida qasiyaha xiirid sare, ayaa laga yaabaa in loo isticmaalo marxaladdan habka si loo sameeyo emulsion-ka mid aad u fiican, cidhiidhi ah oo adag, iyo si loo hubiyo xidhiidhka wanaagsan ee u dhexeeya marxaladda saliidda iyo marxaladda biyaha.Emulsion ganaaxa ee ka soo baxa wuxuu abuuri doonaa margarine tayo sare leh oo soo bandhigaya caag wanaagsan, joogtayn iyo qaab dhismeed.

Bamka ayaa markaa u sii gudbiya emulsion-ga aagga daaqsinka.

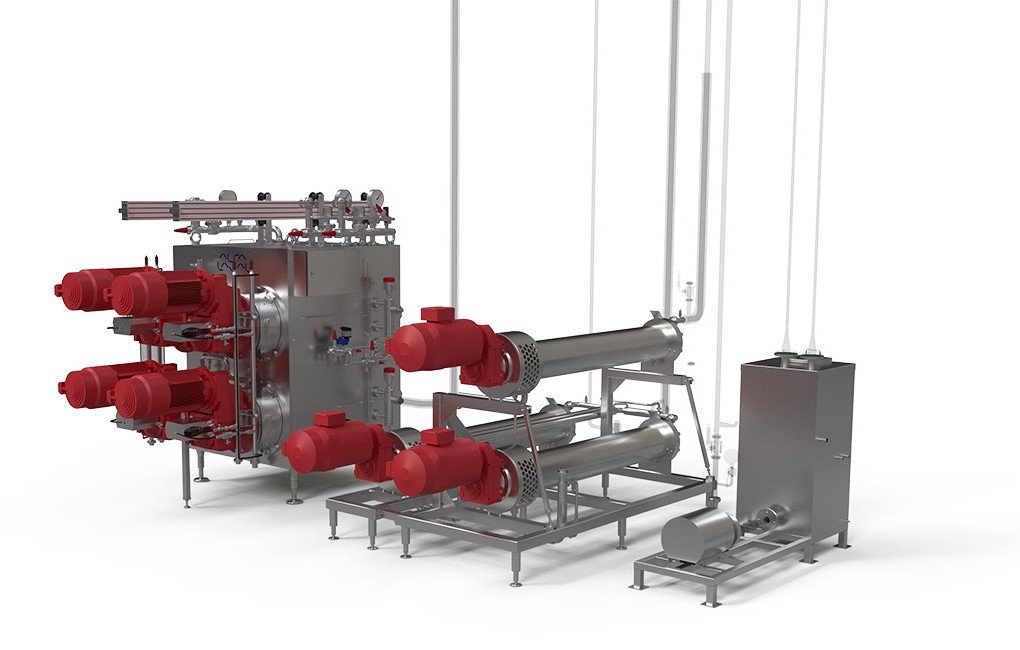

Crystallization ee wax soo saarka margarine

Bamka cadaadiska sarreeya wuxuu u gudbiyaa emulsion-ga si aad u sarreeya kulaylka dusha sare ee la xoqay (SSHE), kaas oo loo habeeyey iyadoo loo eegayo heerka socodka iyo cuntada.Waxaa jiri kara tuubooyin qaboojin oo kala duwan oo cabbirro kala duwan leh iyo meelo kala duwan oo qaboojinta.Dhululubo kastaa waxay leedahay nidaam qaboojin oo madax banaan kaas oo qaboojiyaha (sida caadiga ah ammonia R717 ama Freon) si toos ah loogu durayo.Tuubooyinka alaabtu waxay isku xiraan dhululubo midba midka kale.Dareemaha heerkulka meel kasta oo ka soo baxa ayaa hubiya qaboojinta habboon.Cadaadiska ugu badan waa 120 bar.

Iyada oo ku xidhan habka loo kariyo iyo codsiga, emulsion-ku waxa uu u baahan karaa in uu dhex maro hal ama in ka badan oo unug shaqaale biin ah ka hor inta aan la xidhin.Unugyada shaqaalaha pin waxay xaqiijiyaan balaastikada saxda ah, joogtaynta iyo qaab dhismeedka alaabta.Haddii loo baahdo, Alfa Laval wuxuu keeni karaa tuubo lagu nasto;si kastaba ha ahaatee, alaab-qeybiyeyaasha mishiinada wax-baakaha badankoodu waxay bixiyaan mid.

Unug dib-u-shaqayn joogto ah

Unug dib-u-shaqayneed oo joogto ah ayaa loo qaabeeyey inay dib u dhalaaliso dhammaan badeecooyinka xad-dhaafka ah ee soo maray mishiinka baakadaha si dib loogu habeeyo.Isla mar ahaantaana, waxay ka dhigaysaa mashiinka wax lagu duubo mid ka madax bannaan cadaadis kasta oo aan loo baahnayn.Nidaamkan dhammaystiran waxa uu ka kooban yahay saxan-wareega kulaylka, bamka biyaha dib u wareegaya, iyo kuleyliyaha biyaha.

Waqtiga boostada: Jun-21-2022