Habka Soo saarista Margarine

Habka Soo saarista Margarine

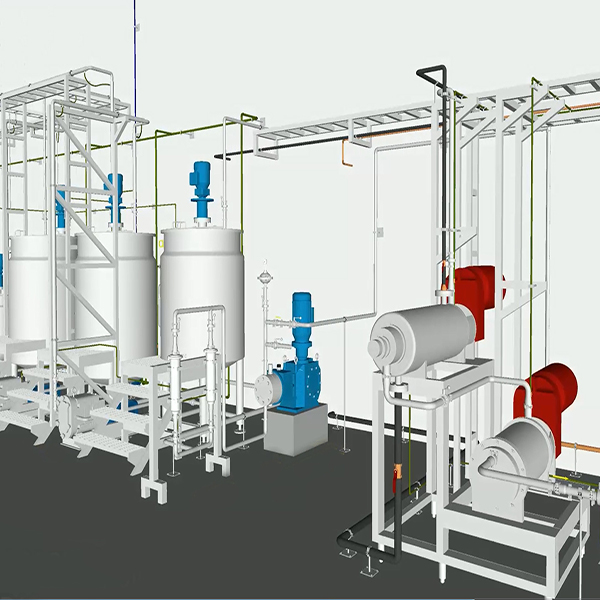

Wax soo saarka Margarine wuxuu ka kooban yahay laba qaybood: diyaarinta alaabta ceeriin iyo qaboojinta iyo balaastiga. Qalabka ugu muhiimsan waxaa ka mid ah taangiyada diyaarinta, bamka HP, cod-bixiye (kuleelka dusha sare ee la xoqay), mishiinka rotor-ka, unugga qaboojinta, mashiinka buuxinta margarine iyo iwm.

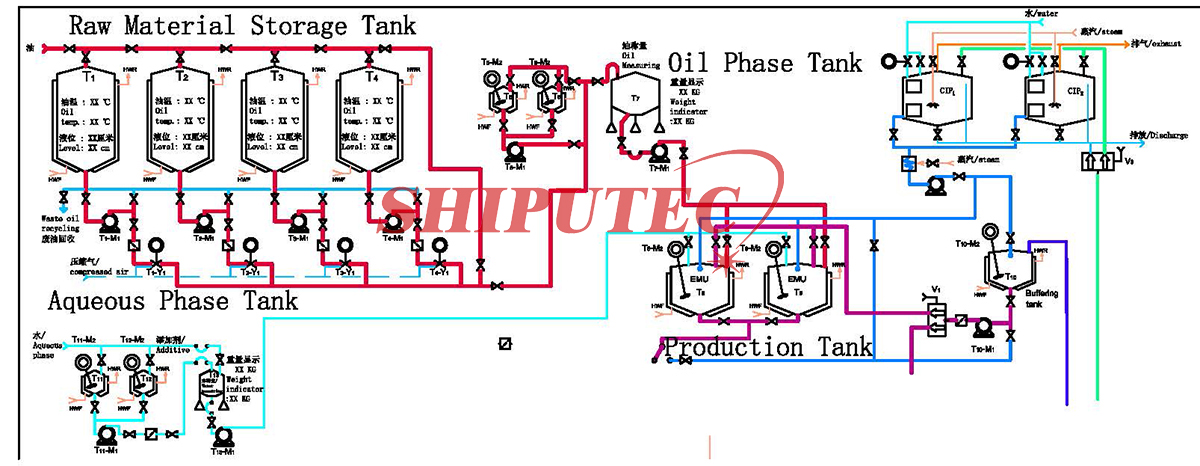

Nidaamkii hore waa isku dhafka wejiga saliidda iyo wejiga biyaha, cabbirka iyo isku dhafka isku dhafka ee wejiga saliidda iyo wejiga biyaha, si loogu diyaariyo quudinta walxaha habka dambe. Habka ugu dambeeya waa qaboojinta joogtada ah ee balaastikada iyo baakadaha alaabta.

Habka diyaarinta alaabta ceeriin ee margarin ayaa lagu muujiyay sawirka 1:

- 1.Caanaha khamiirsan

Qaar ka mid ah caanaha margarine si loogu daro caanaha, iyo caanaha ka dib bakteeriyada lactic acid halsano waxay soo saari karaan dhadhan la mid ah kareemka dabiiciga ah, sidaas darteed warshadda caanaha khamiirsan iyo biyo isku dhafan.

- 2.Isku dhafka biyaha

Waxyaabaha lagu daro biyaha iyo biyaha ku milma ee caanaha margarine, sida caanaha khamiirka ah, milixda, waxyaalaha lagu ilaaliyo, iwm, ayaa lagu daraa isku dhafka wajiga biyaha iyo haanta cabbirka ee qiyaasta loogu talagalay in la walaaqo oo la isku daro, si markaas wajiga biyaha qaybaha waxaa lagu kala diraa xal isku mid ah.

- 3.Isku dhafka wajiga saliidda

Saliida ceeriin ee tilmaamo kala duwan ayaa marka hore lagu dhex daraa haanta isku dhafka saliidda iyadoo loo eegayo saamiga loo qoondeeyay, ka dibna waxyaabaha lagu daro saliidda-milmi kara, sida emulsifier, antioxidant, pigment saliid milmaya, cellulose saliid-milaysa, iwm, ayaa lagu daraa wejiga saliidda marka loo eego saamiga, oo lagu qaso haanta cabbirka, oo la walaaqay si loo sameeyo weji saliid isku mid ah.

- 4.Emulsion-ka

Ujeedada emulsification ee margarine waa in la sameeyo wejiga aqueous si siman oo xasilan u kala firdhiyey wajiga saliidda, iyo heerka kala firdhisan ee wejiga aqueous ayaa saamayn weyn ku leh tayada alaabta. Sababtoo ah dhadhanka margarine waxay si dhow ula xiriirtaa xajmiga qaybaha wajiga biyaha, faafinta bakteeriyada waxaa lagu fuliyaa marxaladda biyaha, xajmiga bakteeriyada guud waa 1-5 microns, sidaas darteed dhibcaha biyaha ee 10-20 microns ama kala duwanaansho yar ayaa xaddidi karta faafinta bakteeriyada, sidaas darteed kala firdhinta wajiga biyuhu waa mid aad u fiican, qaybaha wajiga biyuhu aad bay u yar yihiin waxay ka dhigi doonaan margarine lumin dhadhan; Kala firdhinta kuma filna, qaybta biyaha wejiga aad bay u weyn tahay, waxay ka dhigi doontaa margarine metamorphism kharriban. Xidhiidhka u dhexeeya heerka kala firdhisanaanta wejiga aqueous ee margarine iyo dabeecadda alaabtu waa qiyaas ahaan sida soo socota:

| 水滴直径 Cabbirka dhibicda biyaha (Mikrometer) | 人造奶油性质 (Dhadhanka Margarine) |

| in ka yar 1 (qiyaastii 80-85% wajiga biyaha) | Culeys iyo dhadhan yar |

| 30-40 (in ka yar 1% wajiga biyaha) | Dhadhan wanaagsan, fududahay in la kharribo |

| 1-5 (qiyaastii 95% wajiga biyaha) | Dhadhan wanaagsan, ma fududa in la kharribo |

| 5-10 (qiyaastii 4% wajiga biyaha) | |

| 10-20 (qiyaastii 1% wajiga biyaha) |

Waxaa la arki karaa in hawlgalka emulsification waa in uu gaaro heer gaar ah shuruudaha kala firdhiso.

Ujeedada isku dhafka biyaha iyo wejiga saliidda si gooni ah iyo si siman wejiga hore waa in la hubiyo joogteynta isku midka ah ee emulsion oo dhan ka dib marka la isku daro oo la isku daro saliidda iyo biyaha laba weji. Isku darka Emulsification waa, dhibaatada hawlgalka waa 50-60 digrii, marxaladda biyaha waxaa lagu daraa marxaladda saliidda la qiyaasay, ee walaaqaya mashiinka mashiinka ama wareegga bamka, waa marxaladda biyaha si buuxda u kala firirsan tahay wajiga saliidda, sameynta cinjirka. Laakin dareeraha cinjirka ah ee noocaan ah aad buu u deggan yahay, joojinta walaaqda waxaa laga yaabaa inay ku jirto goobta ciyaarta ee saliidda iyo ifafaalaha kala soocidda biyaha.

Ka dib marka emulsion isku dhafan la keeno, habka qaboojinta iyo balaastigga ayaa la sameeyaa ilaa alaabta la baakadeeyo.

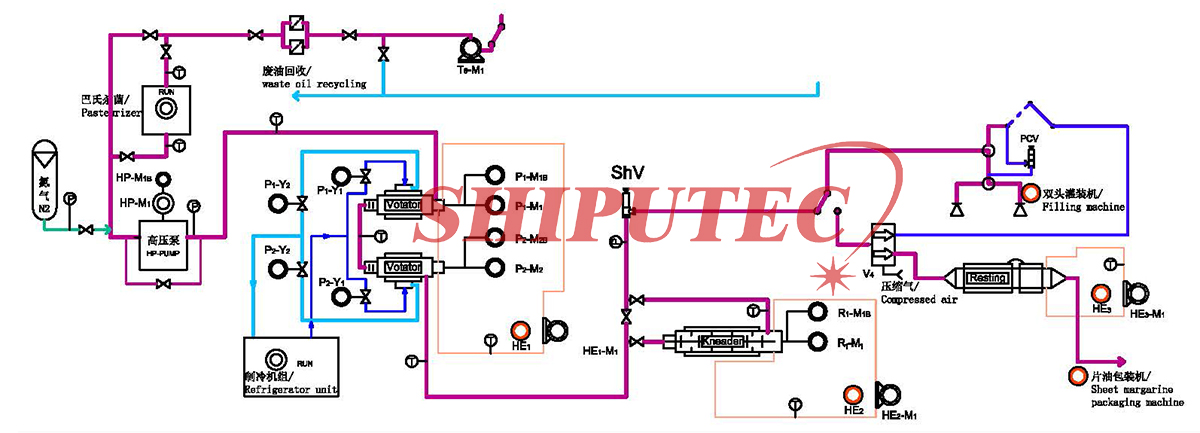

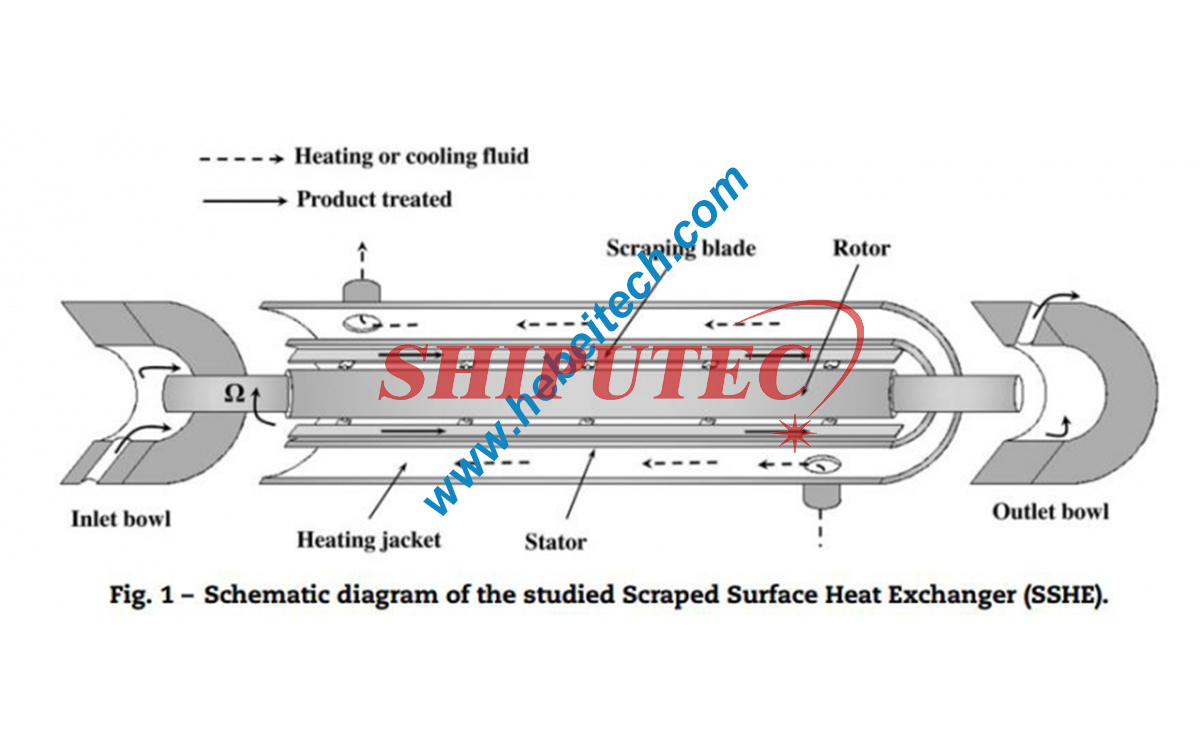

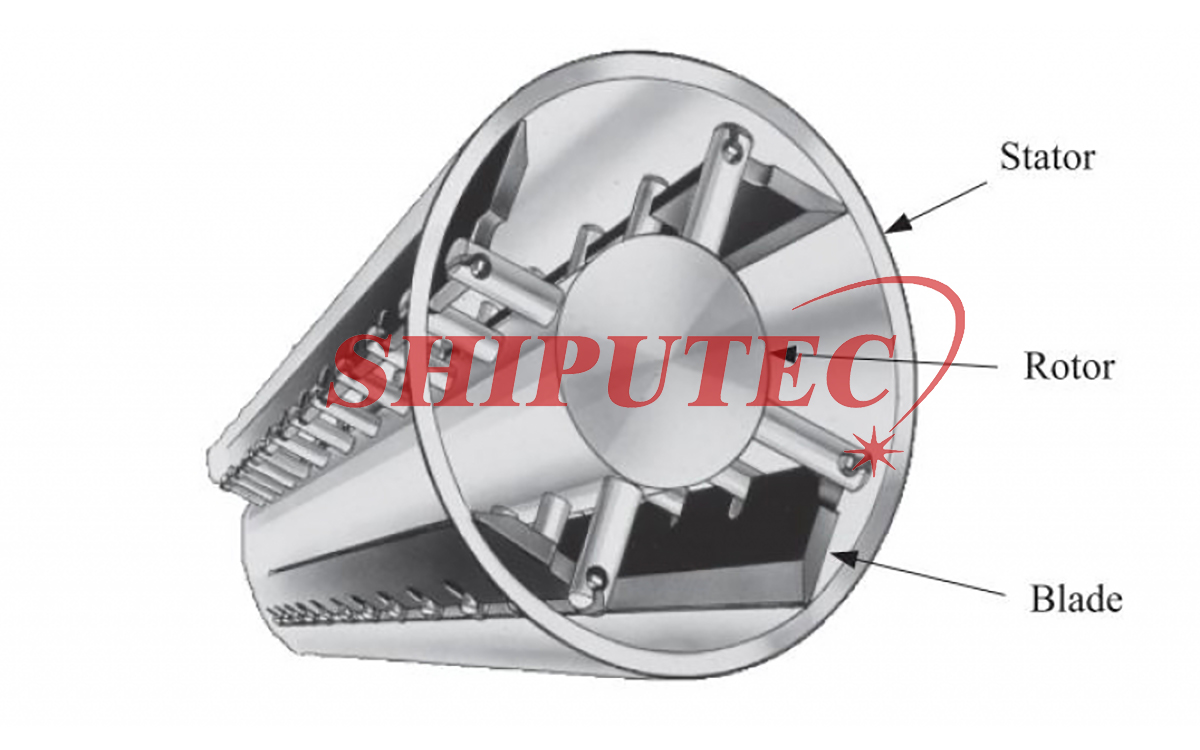

Emulsion-ka waa in la qaboojiyaa oo balaastig lagu sameeyaa si loo soo saaro badeecad margarine dabacsan. Waqtigan xaadirka ah, waxay inta badan qabataa qalabka balaastigga ee joogtada ah ee deminta, oo ay ku jiraan codbixiye ama loo yaqaanno kulaylka dusha sare ee la xoqay (cutub A), mishiinka rotor-ka ama mashiinka cajiinka (cutubka C) iyo tuubada nasashada (cutubka B). Habka farsamada waxa lagu muujiyay sawirka 2:

Qalabkani wuxuu leeyahay sifooyinka soo socda:

1. Cadaadis sare oo hawo joojin ah oo joogto ah

Emulsion-ka premixed waxa lagu quudiyaa dhululubada deminaya bamka cadaadiska sare ee codbixiyaha. Cadaadiska sare wuxuu ka adkaan karaa caabbinta dhammaan cutubka, marka lagu daro hawlgalka cadaadiska sare wuxuu ka dhigi karaa badeecada khafiif ah oo siman. Hawlgalka xiran wuxuu ka hortagi karaa hawada iyo hawada sababtoo ah deminta iyo uumiga biyaha lagu qaso emulsion, hubi shuruudaha caafimaadka alaabta, yaraynta lumitaanka qaboojiyaha.

2. Deminta iyo emulsification

Emulsion-ka waxaa lagu demiyaa ammonia ama Freon ee cod-bixiyaha si uu u qaboojiyo emulsion-ka si degdeg ah, si wax-soo-saarka qaybo yaryar oo crystalline ah, guud ahaan 1-5 microns, si dhadhanku u jilicsan yahay. Intaa waxaa dheer, xoqidda on usheeda dhexe wareeg ah ee cod-bixiyaha si dhow ula xiriirin derbiga gudaha ee dhululubo, sidaas xoqidda ee hawlgalka ma aha oo kaliya si joogto ah u xoqin karaa crystallization dheggan derbiga gudaha, laakiin sidoo kale ka dhigi emulsion kala firdhiyey si ay ula kulmaan shuruudaha emulsification ee codka.

3. Kneading and dethickening (pin rotor machine)

Inkasta oo emulsion-ka qaboojiyey codbixiye uu bilaabay inuu soo saaro crystallization, waxay weli u baahan tahay inay koraan iyada oo loo marayo muddo wakhti ah. Haddii emulsion-ka loo oggolaado inuu kristeed ku nasto, shabakad adag oo kiristaalo ah ayaa samaysan doonta. Natiijadu waxay tahay in emulsion-ka la qaboojiyey uu sameyn doono tiro aad u adag oo aan lahayn caag. Sidaa darteed, si loo helo badeecada margarine oo leh caag gaar ah, qaab dhismeedka shabakada waa in la jebiyaa habab farsamo ka hor inta emulsion-ku sameeyo qaabka guud ee shabakada, si loo gaaro saameynta yaraynta dhumucda. Burinta iyo dhumucda ka saarista waxaa inta badan lagu sameeyaa mishiinka rotor-ka.

Unugga A (codeeyaha) runtii waa qalab qaboojinta xoqan. Emulsion-ka waxa loo kaxeeyaa qaybta xidhan ee A (codeeyaha) bamka cadaadiska sarreeya. Maaddadu waxay dhex martaa kanaalka u dhexeeya dhululubada qaboojinta iyo wareegga wareegga, iyo heerkulka maaddadu si degdeg ah ayuu hoos ugu dhacayaa by deminta dhexdhexaadiyaha qaboojinta. Laba saf oo xoqan ayaa lagu habeeyey dusha sare ee usheeda. Kiristaalo ka sameysan dusha gudaha ee cod-bixiyaha waxaa iska xoqaya xoqida xawaaraha sare leh si ay mar walba u soo bandhigto dusha qaboojinta cusub oo ay u ilaaliso wareejinta kulaylka hufan. Emulsion-ka waxaa lagu kala firdhi karaa ficilka xoqida. Marka maaddadu ay dhex marto cutubka A (codeeyaha), heerkulku wuxuu hoos ugu dhacayaa 10-20 darajo, taas oo ka hooseysa barta dhalaalaysa ee saliidda. Inkasta oo saliiddu ay bilaabato inay dhalaaliso, haddana weli may samayn xaalad adag. Waqtigaan, emulsion-ku wuxuu ku jiraa xaaladda qaboojinta waana dareere qaro weyn.

dhidibka wareega ee cutubka A (codeeyaha) waa dalool. Inta lagu jiro hawlgalka, biyo kulul oo ah 50-60 digrii ayaa lagu shubaa bartamaha dhidibka wareegga si looga hortago crystallization bond oo lagu daaweeyay dhidibka oo keena xannibaad.

Cutubka C (mashiinka rotor-ka pin) ayaa cajiin iyo dhumuc ka saaraya, sida ku cad shaxanka sare. Laba saf oo bir ah ayaa lagu rakibay biraha wareegtada ah, waxaana lagu rakibay darbiga gudaha ee silsiladda birta oo aan is taaban. Marka shafka uu ku wareego xawaare sare, biraha birta ah ee ku yaala shafka ayaa ka gudbaya farqiga birta birta ah ee go'an, walxaha si buuxda ayaa loo cajiin karaa. Ficilkan hoos yimaada, waxay kor u qaadi kartaa kobaca kiristaalo, waxay burburin kartaa qaab dhismeedka shabakada crystal, samee crystals-joojin, waxay yaraynaysaa joogteynta, waxayna kordhisaa caagagga.

Cutubka C (mashiinka rotor-ka pin) waxa kaliya oo uu ku ciyaaraa saamayn cajiin xoog leh habeenka aadka u qabow, marka waxa ay u baahan tahay oo kaliya ilaalinta kulaylka umana baahna qaboojin. Sida kulaylka crystallization la sii daayo (qiyaastii 50KCAL/KG), iyo kulaylka ka dhalanaya khilaaf, heerkulka dheecaan ee unugga C (pin rotor macjhine) ayaa ka sarreeya heerkulka quudinta. Waqtigaan, crystallization waa qiyaastii 70% dhamaystiran, laakiin weli waa jilicsan. Alaabta ugu dambeysa waxaa lagu sii daayaa waalka extrusion, waxayna noqon doontaa mid adag ka dib wakhti go'an.

Ka dib marka margarine laga soo diro cutubka C (mashiinka rotor pin), waxay u baahan tahay in kulayl lagu daweeyo heerkul gaar ah. Guud ahaan, badeecada waxaa lagu meeleeyaa heerkul ah 10 darajo oo ka hooseeya barta dhalaalka in ka badan 48 saacadood. Daaweyntaan waxaa loo yaqaana bislaanshaha. Alaabta la kariyey waxaa si toos ah loogu diri karaa warshadda cuntada si loogu isticmaalo.